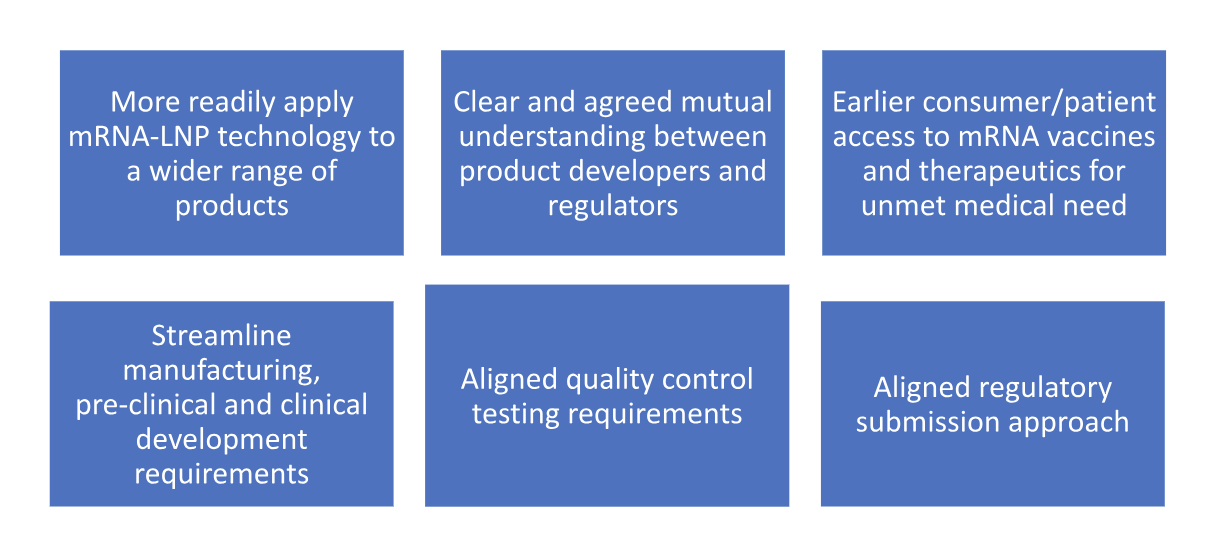

RNA-lipid nanoparticle (LNP) products form a platform technology because the development process is very similar for products for different diseases and conditions. Clarifying the data required for regulatory submissions is critical to provide a predictable development pathway. Benefits will include reduced development and regulatory costs, faster consumer access, and more nimble development of products for pandemics, rare diseases, and cancers where alternatives may not exist.

A working group comprising representatives of Australian federal and state government, global and Australian industry (Moderna, Pfizer, Sanofi, CSL Seqirus), Australian academia (universities of Melbourne, Western Australia, New South Wales, Monash), a clinical research organization (Bellberry), and an industry association (AusBiotech) met several times in late 2023 and early 2024 to discuss principles of mRNA product development and regulatory review.

This article proposes a set of platform development and regulatory requirements for a range of mRNA products. Similar noncoding mRNA sequences and LNPs and largely unchanged manufacturing and analytical methods are typically utilized in mRNA product development. This enables experience with manufacturing, quality controls, and preclinical and clinical development to be adapted for other products. Comparability and bridging studies can be used when the mRNA-LNP composition differs, in the same way that immuno-bridging was used for COVID variant mRNA vaccines.

Regulators have recognized the need to apply platform technologies to mRNA products, but specific guidance has not yet been developed. However, it has been defined more generally. For example: “A platform technology is eligible for designation by FDA if it is incorporated in, or utilized by, an approved drug or biologic, has the potential to be used with more than one drug without an adverse effect on quality, manufacturing, or safety, and has a reasonable likelihood to bring significant efficiencies to the drug development or manufacturing process and to the review process” (s506k of the US Federal Food, Drug, and Cosmetic Act and s2503 of the US Federal Prepare for and Respond to Existing Viruses, Emerging New Threats, and Pandemics Act).

The 2022 US Food and Drug Omnibus Reform Act requires FDA to create a designation program for platform technologies, while the recent European General Pharmaceutical legislation is anticipated to provide a legal definition of platform technology. In 2023, EMA consulted publicly on development of a guideline on quality aspects of mRNA vaccines.

The WHO Expert Committee on Biological Standardization has also defined platform technology for prophylactic mRNA vaccines. EMA has developed vaccine platform technology master file requirements for veterinary vaccines, and use of sponsor master files for human vaccines and other medicinal products has been proposed by the European Federation of Pharmaceutical Industries and Associations (EFPIA), CEPI, and Vaccines Europe. Using these approaches for mRNA platform data could facilitate and reduce regulatory procedure and timeframes.

Platform Technology in mRNA Regulatory Submissions and Review

The extent to which platform approaches can be utilized in regulatory submissions depends on the degree of similarity between the structural composition, intended effect, manufacturing process and product quality, and proposed context of use between different products. For all mRNA products, data on cell banks for bacterial culture and plasmid amplification, plasmid DNA template for mRNA synthesis, bulk purified RNA, and mRNA encapsulation into LNPs is required.

Regulators expect potency testing of mRNA products at release and during stability testing. It is critical to demonstrate that the mRNA expresses a complete protein of correct identity without significant truncated or alternative sequences. While many in-process controls are required for mRNAs and LNPs, once testing methods are developed, most of these controls can be reused.

Regulators will require clinical data, except for variant vaccines. The maximum tolerated patient dosage can be used in a platform approach for a related product. In some cases, a combination of information about the disease, product biological effects, and pharmacokinetic and pharmacodynamic data may be sufficient to leverage existing safety data for a new population.

Vaccine developers can leverage information such as analytical, nonclinical, and clinical data on changes made to an mRNA sequence from a platform product that has a shared mechanism of action, indication, and route of administration. The same manufacturing process controls and analytical methods could be applied for all stages of product manufacture. Nonetheless, a comparability assessment should be conducted. Identity testing and analysis of expression levels of the protein is also required. New nonclinical data could be limited to single-species bridging studies for toxicology, or pharmacodynamic or pharmacokinetic endpoints. Surrogate endpoints such as neutralizing antibodies for vaccines can be used, and human data should not be required by regulators for updates.

Bi- and multivalent products for the same indication (e.g., bivalent COVID vaccine, influenza vaccines)

These products can largely be treated as monovalent products, but it is critical to ensure that each mRNA is manufactured consistently. Identity and potency assays should distinguish each sequence and its products. Vaccine assays should either assess the contribution of each component to the immune response to each antigen or demonstrate that the bivalent vaccine has a noninferior response to the variant antigen.

Products with different mRNA sequence for different indications (e.g., respiratory syncytial virus)

The developer must consider whether the sequence change impacts process and analytical control strategies. Manufacturing process controls, analytical test methods, and qualification of analytical methods for each stage (e.g., DNA template manufacture, mRNA encapsulation) should be consistent with the mRNA platform product and for the LNP manufacturing stage. Identity testing is molecule-specific, and the expression test will require method qualification.

Even for a combination of existing mRNA-LNP products, regulators will require additional nonclinical and clinical data if a new indication is proposed. While pharmacology, toxicology, and biodistribution data regarding mRNA-LNP components common to other platform products could be leveraged, a biodistribution study with the new mRNA sequence may be required by the regulator.

Bivalent or multivalent products for different indications (e.g., cytomegalovirus, Lyme disease vaccines, norovirus vaccines, tumor-associated antigens, monoclonal antibodies)

Data requirements vary depending on whether the mRNA sequences have been part of platform products with regulatory approval or target closely related indications to preceding mRNA products. mRNAs may be co-formulated either within a single LNP or as an admixture of mRNA-LNPs. For admixtures, there is no change to the upstream manufacturing processes, although information on the mixing step is critical. For co-formulation, assurance is required around encapsulation efficiency. Developers need to assess possible interactions of individual mRNA components on protein expression, purity, potency, and stability. If combining two or more existing mRNA sequences, a developer can rely on previously established manufacturing processes and analytical control strategies. The identities and quantities of each mRNA and their expressed products must however be determined.

For a product that combines existing mRNA-LNPs, respective nonclinical and clinical data can be leveraged, but regulators usually require new clinical trial data. A single-species bridging study to demonstrate that biodistribution and toxicological characteristics of the components are maintained could be required. The regulatory submission must also include a scientific and clinical rationale for the combination as well as investigation of potential for interaction between products. New mRNA sequences will require new clinical and nonclinical data in the regulatory submission.

Considerations for self-amplifying mRNA (sa-mRNA) products (e.g., some COVID-19 vaccines)

sa-mRNA products contain mRNA for enzymes that replicate the therapeutic mRNA after transfection. Regulatory submissions will require data on the self-amplifying replicon genes as well as the RNA for the gene of interest, whether the two mRNAs are encoded on the same or different mRNA strands (and LNPs); and on degradation of the (longer) sa-mRNA sequences. Because of greater persistence of sa-mRNA, significant toxicological and biodistribution studies and information on the duration of immune response may be required. Unless the manufacturer is bridging from another sa-mRNA product, genotoxicity and pregnancy data may be required, along with a full clinical module in the submission.

LNP variation

Data on the formulation of the LNP and encapsulation of the mRNA are expected to be required for the first platform product from each developer. If LNPs of the same size and composition are used for subsequent products, encapsulation data can be extrapolated for regulatory purposes. When products have significant changes to mRNA length or structure, similar manufacturing processes will often be used, although in some cases different LNPs may be required. If manufacturing methods or the size or composition of LNP changes, then bridging data will be required, in particular to demonstrate biodistribution and toxicological behavior of the new LNP.

If LNPs are augmented with components such as antibodies, anticipate that detailed manufacturing data will be required. Full toxicological data will also need to be submitted for evaluation if a novel lipid is used. If LNP formulations are modified to increase delivery of mRNA to specific cell types, regulators will request data on influences on protein expression and its localization. Clinical data requirements relating to changes in LNP composition, size, or functionality will be informed by preclinical studies, as well as the nature of the disease or condition being treated.

Particular considerations for mRNA therapeutics and oncology immunotherapeutics

Therapeutics under development for cancers and genetic diseases will require chronic, repeat administration and higher mRNA doses. While platform aspects should reduce the need for generation of new data, more extensive pharmacokinetic, repeat-dose toxicology, and genotoxicity data are likely to be required. Delivery to target organs including biodistribution studies and information on duration of protein expression and its relationship with product efficacy in animal models of the target disease should be documented. Data on immune activation by repeat doses may be required.

When using mRNA technology for rare diseases, the expressed product often provides a functional replacement enzyme. In the context of the rarity of these diseases, from a regulatory standpoint, rather than considering every single mRNA therapy encoding for a single enzyme as a separate product, these could be grouped into a single “umbrella” product that would cover a range of enzymes pertaining to the same metabolic cycle.

In personalized mRNA cancer immunotherapy, individual tumor-specific neoantigen sequences are used to enhance the immune response. Regulators will be required to adapt their Good Manufacturing Practice oversight to review facilities that conduct simultaneous very small-scale manufacture as well as modify their approach to review because every product comprises a unique set of sequences.

Conclusions

Experience with mRNA COVID variant vaccines has shown that a platform approach can streamline regulatory review without safety risks or efficacy concerns. Establishing a consensus definition among regulators and developers of platform technology specific to mRNA vaccines and therapeutics is critical because many mRNA products target significant unmet needs including major viral diseases of global significance, metabolic diseases, and serious cancers. This platform approach recognizes that because of the similarities in mRNA-LNP structure and composition between products even for very different indications, there are many common elements of mRNA product design, development, and manufacturing. This can significantly streamline development, manufacturing, and quality assurance steps for products, as well as their regulatory review.

However, given the diversity of potential mRNA-LNP product types and therapeutic applications, a number of product-specific requirements (including regulatory requirements), even with the application of platform technology, will remain. The working group intends to socialize the elements in this written piece with regulators and other government bodies with the intention of supporting the creation of specific guidances on mRNA platform product regulation.